East Wastewater Treatment Plant Capacity Expansion

CLIENT: City of Evansville, IN

The City of Evansville owns and operates their East Wastewater Treatment Plant, which treats a fraction of the City’s wastewater and combined storm sewers by providing screening and grit removal, primary treatment, secondary treatment using activated sludge, and disinfection. Solids handling (digestion, dewatering, and storage) is also provided at this plant for the waste solids from both the East and West WWTPs. The East WWTP also houses administrative offices and a septic and fats, oils, and grease receiving station. Septage and FOG are treated directly in the plant digesters, and biogas is reused in CHP engines.

The City signed a Consent Decree with IDEM, USEPA, and the US Department of Justice to comply with the requirements of the Clean Water Act by reducing sewage overflows and implementing upgrades to the plant. For the East WWTP that meant providing full secondary treatment for flows up to 40 MGD. Since pre-project flows were limited to 22 MGD (the capacity of the existing disinfection system), it was necessary to increase the east plant capacity by approximately 18 MGD.

The primary objectives of this project were to upgrade the plant to meet the requirements of the Consent Decree as well as ancillary improvements that have been identified. Improvements included:

- Treatment Capacity Expansion – Added a new biological aerated filter (BAF) to expand secondary treatment capacity. The City of Evansville is very comfortable with BAF technology and has used it at their West WWTP since an expansion Clark Dietz did for them in 2008. The benefit of this system is that it provides secondary treatment and filtration in a single unit and avoids the need for both aeration basins and clarifiers. It is also highly automated and operator-friendly.

- Disinfection Upgrade and Expansion – Upgraded to UV disinfection housed in an existing chlorine tank. During preliminary design a number of different UV technologies were evaluated and UVT was monitored. The Trojan Signa system was selected because of its robustness, relatively few number of bulbs, and to be consistent withe the City’s West Plant equipment. Relocated the plant water pumps and reconnected new plant water pumps to the existing plant water system.

- Grit Removal Improvements – Reduced the primary sludge grit loading to the three existing anaerobic digesters by adding grit removal to the primary sludge system. This was accomplished by taking less concentrated primary sludge through a hydrocyclone to remove grit, then thickening the degritted sludge in rotary drum thickeners. This thickened the de-gritted sludge to increase digester capacity and reduce digester cleaning costs.

- Hydraulic Bottleneck Correction – Removed potential hydraulic bottlenecks to achieve 40 MGD capacity including a new influent flow meter, modifying primary clarifier effluent weir elevations, and influent piping to one of the aeration basins.

- Effluent Hydraulic Improvements – Increased current conveyance capacity utilizing the existing effluent pipes. Lined the existing effluent pipes.

- Secondary Control Building Upgrades – Upgraded the RAS/WAS pump system to match the West Plant secondary control building systems. Upgrades included replacing all of the RAS pump and suction and discharge header piping and valves. Automation was added to control pump speed either via flow pacing, constant rate, or sludge blanket depth. The WAS pumps were eliminated and controls and valving were added so that WAS can be pumped with RAS pumps.

- Phosphorous Removal Upgrades – Added phosphorous removal chemical feed systems.

- Power and Electrical Feed Improvements – Upgraded the power supply plant electrical feeds.

- Aeration Tank Selector Zone – Evaluated adding anaerobic selector zones to the aeration basins to control filamentous bacteria growth.

- Secondary Clarifier Distribution Upgrades – Added new MLSS channels to optimize clarifier loading and performance.

- Sidestream Equalization – Added a sidestream equalization tank to collect and meter centrate and digester supernatant to equalize ammonia loads through the week and improve treatment performance.

- Life Safety and Code Compliance – Each upgraded or new unit process was assessed to comply with NFPA 820 and, in the case of occupied buildings, building code. Life safety considerations included safety grating and hatches, non-corrosive materials, avoidance or minimizing trip hazards, appropriate egress, lighting upgrades, hazardous gas monitoring and alarms, and security camera addition.

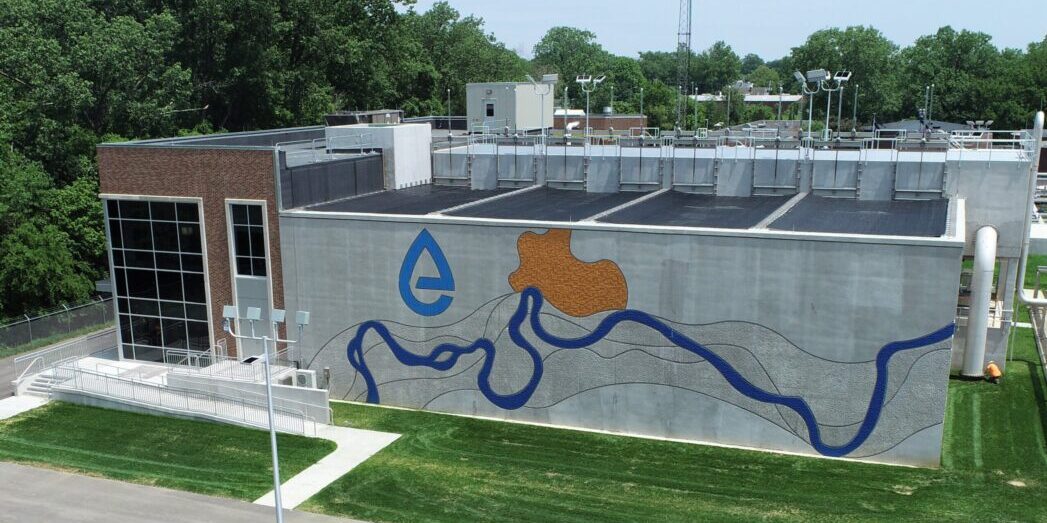

- New Administration Building – A new administration building was added adjacent to the BAF structure. This brings the administration building to the main entrance of the plant to make it easier for visitors and deliveries to securely enter the facility. A model of the BAF treatment system is located in the building lobby and that, combined with a viewing area for the pipe gallery, will facilitate education for the facility. The building also includes a reception area, administrative offices, a large and small conference room, control and electrical rooms, and a kitchenette. The parking area for the administration building includes several new EV chargers. The new administration building also allows the City to convert and upgrade the old building to operator offices.

Awards

2022 ACEC Indiana State Finalist Award

2024 ACEC National Recognition Award